26*6m 冷床

產(chǎn)品簡介:

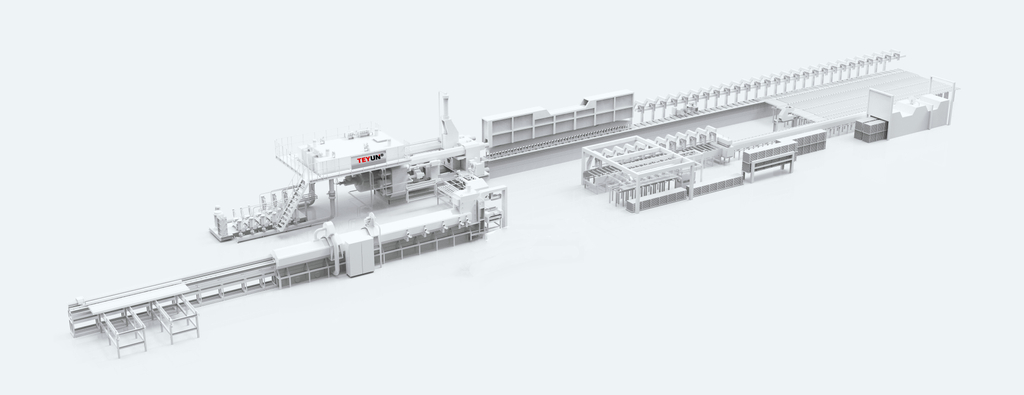

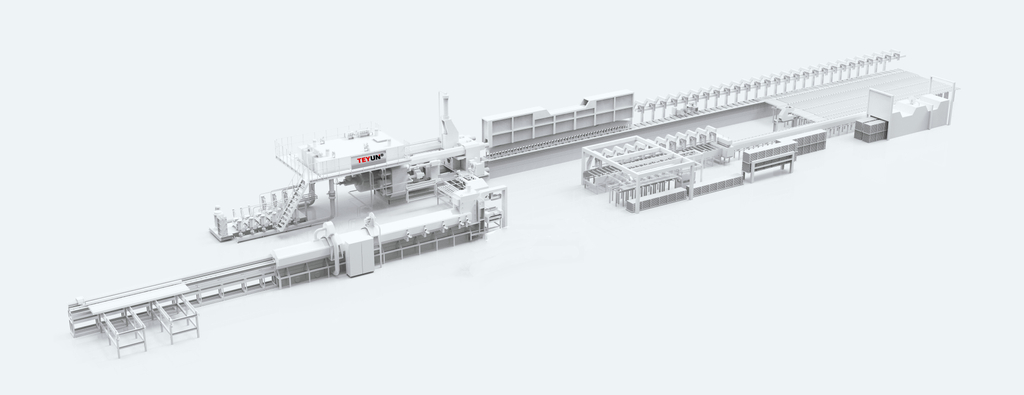

The automatic aluminum extrusion cooling table (26*6m) is one part of the aluminum extrusion line which is mainly used for cooling and conveying the aluminum profile which realizes the straightening and cutting of the aluminum material through the cooperation of the tractor, the straightening machine, the interrupting saw and so on.

冷床主要有以下幾部分構(gòu)成:

1.初出臺���、冷卻裝置

- 初出臺配高溫毛氈滾筒

- 可調(diào)式升降臺,根據(jù)不同型材調(diào)節(jié)高度��。

- 夾緊器2套

- 冷卻系統(tǒng)為上下風(fēng)冷卻����。

2.滑出臺

- 滑出臺由液壓升降裝置組成

- 升降裝置為液壓驅(qū)動式,滾道臺垂直升降����。

- 升降高度50mm

3.取料臺

- 移料臺是把材料從滑出臺移到冷卻臺的裝置

- 傳動軸:φ35

- 鋁梁彩色噴涂

- 不需拆裝任何部件直接更換毛氈

4.Cooling Bed

The cooling bed is mainly responsible for the cooling of the profile. The conveyor belt is driven by a chain, and the chain is a double-row chain.It can automatically adjust the discharging distance and the profile is moved by a belt-type aluminum alloy feeding mechanism.

5.Straightening Table

The straightening machine adopts cross-stretched belt-type aluminum alloy feeding material across the bridge, equipped with a gear transmission mechanism. Its discharge spacing can be adjusted and the belt can be controlled in forward and reverse rotation.

6.Straightening Machine

The straightening machine is mainly used to stretch the aluminum profile to make it straight and obtain good straightness.The straightening machine is divided into fixed front jaws and moving rear jaws. The track base is made of steel plate and section steel welded structure. There is a steel guide rail above the base, which can withstand the force generated when it is stretched.The two straightening heads are each equipped with a hydraulic station.

- Sloping with hydraulic lifting, driving high -temperature drums with a chain.

- Slide the platform to adopt a high temperature drum to reduce the wear of the roller due to high temperature.

- Use belt -type temperature -resistant felt to reduce the wear of aluminum materials.

- The aluminum profile is shifted and transported to keep the appropriate distance between aluminum profiles.

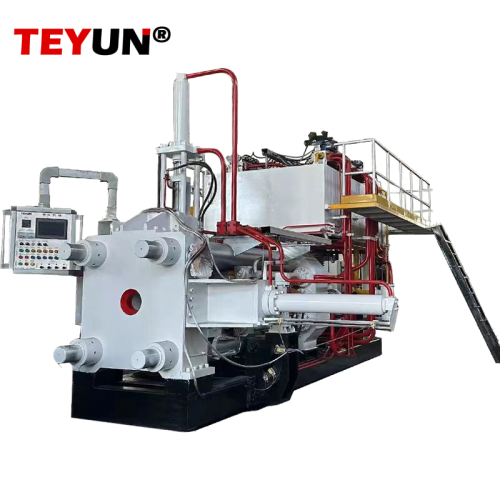

The whole line of the aluminum extrusion line consists of the aluminum extrusion main press, the puller, the automatic cooling table, the heating furance, the mold oven, the aging furance.

地址 : 南京市溧水區(qū)明覺工業(yè)園興業(yè)路

地址 : 南京市溧水區(qū)明覺工業(yè)園興業(yè)路

English

English fran?ais

fran?ais русский

русский espa?ol

espa?ol ???????

??????? 日本語

日本語 Ti?ng Vi?t

Ti?ng Vi?t

支持 IPv6 網(wǎng)絡(luò)

支持 IPv6 網(wǎng)絡(luò)